| Home | | | News | | | Products | | | Services | | | About Us | | | Contact Us | | | Careers |

Visual Inspection System

-

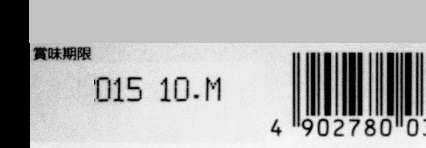

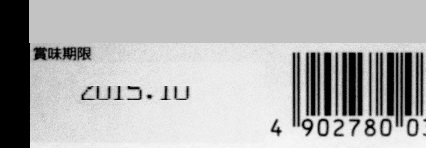

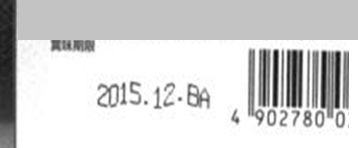

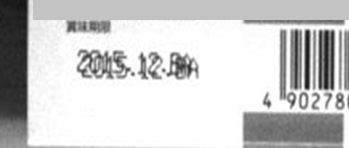

Printing Verification System

- Test Products

-

Food Package, Drink, Medicine, Carton case, and other packing casing

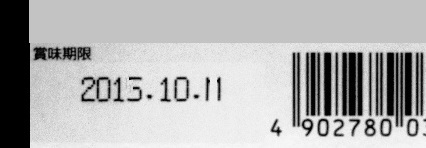

Date of Production ・Consumption time limit ・Expiration date ・Manufacture lot number ・ and other - Target Characters

-

Alphabet, Numbers, Symbols

Stamp, each sizes of inkjet characters - Software functions

- X-Y Position correction, Rotate Position correction, Shading correction, Correction of character expansion and contraction, Single-character segmenting, Blurry text restoration, Calendar, Auto count up, defective log, defective image saving, etc.

- Throughput

- 500 individuals / Minute

- Equipment specifications

-

Controller: Windows8.1 DOS/V-PC

Camera: 1.3M Pixels USB-I/F ☓ 1ch

Work conveying inspection sensor

Alarm Buzzer

Abnormal signal output

Printing String Data external input

Signal lamp attachable

-

Inspection interface

-

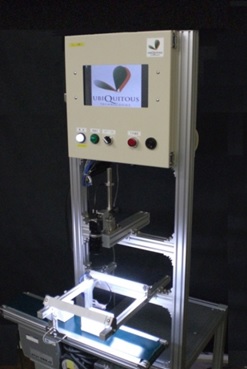

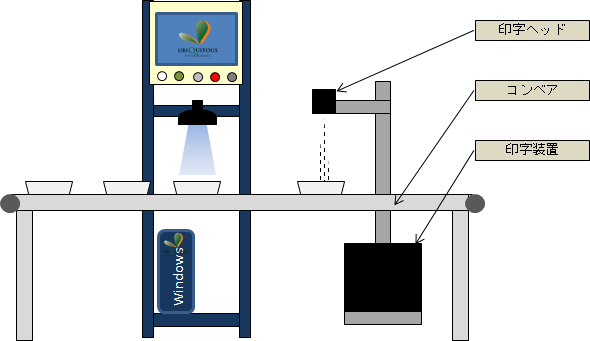

Sample equipment

independent type equipment structure as standard for easy attachment of existing conveyor and transport mechanism

(Ex.) Camera View Angle : 140mm

-

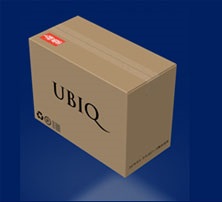

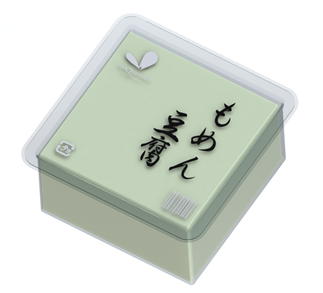

Sample target product

Reusable shipping

carton

Paper

container

Paper

pack

Transparent resin

container

Bag

PackageUBIQ will provide machinery that will meet your needs by designing the it by ourselves. If there are any problems such as unclear printing surface samples, complex reflections, hard time with attaching the inspection camera, please do not hesitate to contact us.

Printing Miss, Printing Omission, Missing text, blurry text, Detection of Printing misregistration

-

Label Checking

-

Inspected defects

Unclear character

Missing character

Half character string

Meandering character

Overlaid character

Positional shift

-

-

Contamination Inspection Equipment

-

Inspects the vinyl, hair, paper and other contaminants in a food packages

- Target products

- Food, Packed lunch, Dairy products、drinks

- Software specifications

- X-Y Position correction、, Rotate position correction, Color extraction correction, Vector correction

- Throughput

- 500 individuals / minute

- Equipment specifications

Controller : Windows8.1 DOS/V-PC

Camera : 1.3M Pixels USB-IF × 4 devices

- Work conveying inspection sensor

- Alarm Buzzer

- Abnormal signal output

- Printing String Data external input

- Signal lamp attachable

-

Sample image

Contaminant will be detected by elliminating unnecessary reflection parts using image processing technology

-

Sample equipment

Portal type

-

-

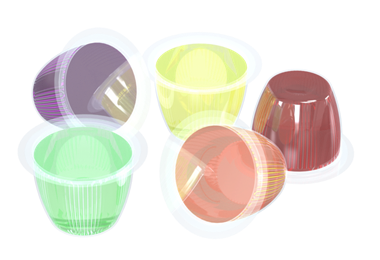

Cup Container Inspection

-

Sample equipment

-

Frame and Control for image processing are One Stop Design from UBIQ

UBIQ will adjust to the customization you desire such as connecting to conveyor, electrical specification, lamp lighting controller, your specified controller, cover coloring, and water even prevention cover attachment.

| Company News |

| 2015.09.04 |

| "New Value Creation Exhibition 2015" will be held on November 18, 2015 (Wednesday) ~ November 20, 2015 (Friday) at the Tokyo Big Site West 3, Hall 4. Deployment of optical equipment application technology and testing equipment for production that uses image analysis technology will be exhibited. |

| 2015.08.28 |

| Ubiquitous Technologies has announced the tracking system "Beacon One". An indoor location monitoring system that uses "Bluetooth Low Enegy" (BLE) Technology. Sales of the Package System is from September 1, 2015. The service is provided by cloud server. |

| 2015.07.02 |

| 2015, June 17(Wednesday) - June 19(Friday), Image processing measurement system, TechMeasure series, TechVMU was displayed on "2015 West Japan Innovation of Manufacturing Technology" at West Japan General Exhibition Center in Kyushu Institute of Technology booth. |

| 2015.04.06 |

| Ubiquitous Technologies Philippines Inc. will participate as a sponsor of the PSIA (Philippine Software Industry Association) in 2015 "Software Development Environment Exhibition (SODEC)". Please come on May 13(Wednesday) - May 15 (Friday) in the Phillippines booth at the Tokyo Big Sight. |

| 2015.03.04 |

| Ubiquitous Technologies will start to sell the "Printing verification inspection equipment". |

| 2015.03.03 |

| On April 1, 2015, Ubiquitous Technologies will begin to sell the "Tabletop image sizer 'UBIQ-TechVMU-500'" as the first product of "Techmeasure" series. |

| 2015.02.17 |

| We would like to say thank you for visiting "'Technical Show Yokohama 2015'" at Pacifico Yokohama on February 4-6,2015. In particular, Printing inspection, Label inspection, Particle inspection, Scratch test, Dent inspection, Burr inspection, Error-proofing, Inquiries such as sheet inspection. On the other hand, we allowed suggestions such as ink jet printing inspection equipment and Area camera, visual inspection equipment in line sensor camera. In addition, we plan to sell such as "tabletop sizer" of low-cost version in the future. |

| 2015.02.04 |

| Line sensor system / Tabletop Image Sizer was displayed on "Technical Show Yokohama 2015" |

| 2015.02.02 |

| We will exhibit the Tabletop Image Sizer, appearance inspection apparatus according to the line sensor camera in "Technical Show Yokohama 2015" at Pacifico Yokohama from February 4-6, 2015. |

| 2014.07.17 |

| July 17, 2014, Ubiquitous Technologies Inc. established "Kyushu Development Center" at Miyakogun, Fukuoka prefecture for the purpose of developing, manufacturing and marketing of FA Inspection Equipment. We could provide the most appropriate inspection equipment and system by our one-stop custom design that includes development, manufacturing, installation and even maintenance of equipment or system such as visual inspection system, image sizer equipment, manufacturing equipment, and production management system. Our image processing technology and visual inspection system using the optical device control technology accumulated by long-time experience could provide flexible customization depending on client's products and its production lines, from simple crack inspection to foreign object detection, aiming for better product quality. |

| 2014.06.27 |

| Development of tabletop size measuring apparatus utilizing the image processing technology was adopted at 2013 fiscal correction small and medium-sized companies and small business manufacturing, commercial and service innovation business. |

| 2014.06.16 |

| Ubiquitous Technologies Inc. and Clover Japon, Inc. released the software "Clover Chord Systems" windows version for master rhythm music and code. |

| 2014.04.04 |

| Ubiquitous Technologies Inc. and (representative director Ishii Tatsuhiko) of Clover Japon Inc. have concluded the alliance of development and marketing of dedicated software "Clover Chord Systems" master rhythm notation and code notation. |

| Links |